Sediment Filter

The sediment filter is a retreated filter which removes ordinary sediments(clay, rust, sand, etc) in the water through 1~10micron(1/1,000mm) pores.

The sediment filter cartridge is easy to change and allows the customers. To verify the filters level of contamination through naked eyes, providing an

high reliability.

| Origin | Korea |

| Model Number | Water Purifier Filter |

| Brand Name | WACO |

Sediment Filter (Service Life / 3Months)

- Characteristics of Sediment Filter Sediment Filter maximized the effect of purification from the initial stage by eliminating minute impurities with the size down to 1µm such as rust, soil, sand and dust and extends the life of filters in the next stages.

- Materials of Filter and its characteristics Sediment Filter manufactured with PP material collects and eliminates significant volume of pollutants by the maximization of pore volume through multiple fiber layer structure of minute RP fiber, and has chemical durability for various chemicals and thermal resistance in view of the characteristics of PP materials.

- Use of PP materials

- Chemical Process

Large quantity filtration of chemicals and filtration of acid and alkali solutions - Oil and Gas

Refining of oild drilling region, and purification of wastewater of oil well - Metal Finishing

Machinery cooling water, plating solution, and filtration of rust stain - Electronics Industry

Pre-treatment before Reverse Osmosis of Manufacturing micro chips and circuit panels, pre-treatment for chemicals, and pre-treatment for hi-tech coating used for magentic tape, floppy disk and optical fiber - Photography

Development, printing of film and sticking solution - Beverages

Refining of milk, beer, wine, refreshing beverages, spring water, syrup and edible oil - Cosmetics

Production of purified water for cosmetics such as mouth was solution, eau de cologne and lotion - Pharmaceuticals

Production of purified water for pharmacueatical industry, refining of reagents, and pre-treatment before Reverse Osmosis

- Chemical Process

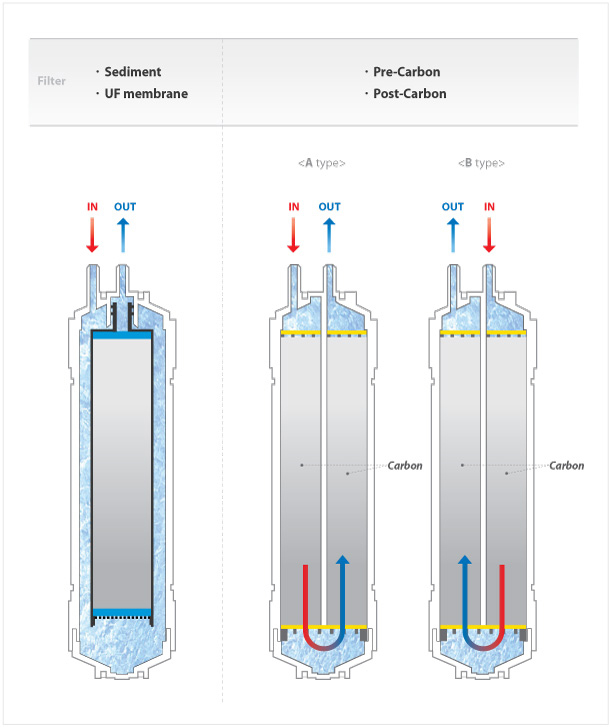

Carbon Filter

Pre-Carbon Filter

The carbon filter uses activated carbons utilizing chemical absorption eliminates the chlorine generated during the process of treatment for the city water and also other organic compounds and odors to make the city water just as natural water.

Post-Carbon Filter

The filter has the function preventing the propagation of germs and eliminating odors melted into water and bad taste, coloring matter and then generate colorless and odorless clean drinking water.

PCB Filter(Post-Carbon block filter)

The filter has the function preventing the propagation of germs and eliminating odors melted into water and bad taste, coloring matter and then generate colorless and odorless clean drinking water.

TCR Filter

By eliminating odors and compounds of taste and colo0r, it provides clean safe water.

Carbon Filter(Service life / 6months)

- Characteristics of Carbon Filter

- Stable (load) even for rapid change in water quality due to high absorption layer and long contact hours

- Wide range of absorption materials due to the application of compound carbon

- Wide range for selection for absorption materials compared to other filters

- Late reaching to destruction point due to stable move of absorption band as absorption layer is high

- Manufacturing cost is slightly higher as it is container feeding type and complexity of manufacturing process

- Principle of Carbon Filter.

- Carbonization and high degree activation of carbon substance or substance that contains carbon substance

- Structure after activation shows well-developed minute stigmata and connection of minute stigmata to passage, and Carbon Filter is absorption agent of

- non-polar nature than polarity due to consolidation of non-fixed form carbon that has wide internal surface area

- Carbon has physical and chemical attraction to particles in the form of gas or liquid around it and the degree of attraction is different dependeng on

- the structure and size of particle of object material. Therefore, mixed substances are eliminated based on the principle of such operation

- Structure of Carbon Filter.

- Absorption property of carbon is based on the shape and surface area of stigmata, and its surface area reachest to 700~1,700

- Distribution of stigmata is classified depending on the size of radius of stigmata by dividing into stingma series with 3 injection

- Manufacturing Process of Carbon Filter

| Inspection for Degree of Carbonization and fixed carbon | Raw material: Coconut foil

Carbonization: Physical change of raw material at 400oC (Carbon Material) Washing: Water washing Drying: Abbreviated dybolism in deficiency electron. |

| Inspection for degree of activation (Absorption power, hardness, and distribution of stigmata) | Activation: 900oC ~ 1,300oC

Activating Agent: Steam, pharmaceuticals Cooling: Rapid cooling with cooling system to avoid oxidization Spallation: User requirements or standard size basis |

| Inspection for size, absorption strength and feeding density | Selection: Classification by size

Packing: Shipping |

PCB Filter(Post-carbon block Filter / Service life 9months)

- Characteristics of PCB filter

Combined with absorption function of carbon and filtration function of block, it is large in surface area, excellent in filtration of pollutants and is constant in its life span. Added with silver, the carbon filter can help to curb the growth of harmful microorganisms in the water through the elution of silver ion, and has antibacterial effect. Its micro-pores of 1micron absorb and filter out smells, residual chlorine, chromaticity, chemical substances, heavy metal particles and carcinogens from the water. - Structural characteristics of PCB filter

As a shaped filter, not in powder, it is strong against impact, abrasion, heat and chemicals. And during its initial use, compared to granular carbon, it hardly releases carbon dusts and does not from flowing path there by leaving no room for germs to live in the filter. Coconut carbon is used as materials in order to enhance the taste of water by eliminating chlorine and bad smells of tap water. Unlike power carbon, it is in block, making it difficult to degrade its characteristics as a filter, and can maintain its function as a filter for a long time. Mostly, post carbon filters for UF method-based, or reverse osmosis-based water purifiers are used. - Definition and structure of PCB filter

PCB refers to a cylinder-shaped activated carbon made by mixing PE resins with pores in its particles and powder carbon and making it plastic at a high temperature.

Nano-pH Filter

Product Hydrogen(H) and reduction to rise up Hydrogen ion density improvement of erase function O3 to anti-oxidation by strengthening(-mV) with ORP-Oxidation Reduction Potential

- Nano-pH Filter : pH 8.0~10 & ORP -100~-200mV

- Durability and Service life : 3,600L

Nature Mineral

- Catalysis for produce hydrogen and creat electric charge operation tourmaline powder

- Magnetite powder can control oxidation and reducing process

- Zeolite powder is high function of an ion replacement(MEQ) by absorption & suction

- Active carbon powder

- Gur bonder (approved FDA) and Mixed bubbly PE binder be produce black filter by compressed sinter method.

Reduction is?

ORP Oxidation Reduction Potential, that is determinant energy in accordance with balance of between the oxidizing agent & a reducing agent in solution as the low numerical value is show strong reduction, high numerical value is show the strong oxidative.

Finally, need the hydrogen (H->H ⦁ H+H2) and keep up balance of mineral to product for alkali Revivification water.

LOHAS Alkali Revivification water is technique an intensive method to formation process as copious as inclusion of mineral and hydrogen(H)

LOHAS water is strong of oxidation-reduction potential reducing rate(ORP -100~-250mV).

The other side Oxidative rate is high that oxidative reduction potential of general water(ORP – +200 ~ +600mV)

Small cluster

Alkali Revivifiction water is dense organization to easily carry by mineral ion action

And speed up metabolism to transpire body wastes. (general water 127Hz = alkali Revivifiction water 62Hz)

Remove Active Oxygen

Active oxygen is hinder activity with primary factor for aging & health by expended oxidative to destructive metabolism in deficiency electron.

SILVER CARBON FILTER

Antibacterial Activated Carbon

Remove Various Bacteria & Antibacteria

- Activated Silver-carbon is Antibacterial Activated Carbon which is split in drinkable activated carbon. Silver Ion (Ag+) has the strongest Antibacterial working in Metal Ions.

- This filter is designed to provide enhanced taste and removal of odors from the purified water.

The Characteristic of Silver activated carbon

– Effective removal of various bacteria (Alcaligenes, Pseudomonas and etc)

– React on automatic charging equipment of Granular Activated Carbon

– Very small amount of dust generation and few extrusion of particle matter.

– Elution of Silver concentration is controlled under 100 ppb by EPA standard

– Suitableness to Japanese Food Additive Test Standard

Basic Properties of Matter

– Shape : Granular Activated Carbon

(Standard granularity size 10/30, 20/40, 30/60, 48/100, 60/150 Mesh)

– Specific gravity : 0.43~0.53g/cc

– Packing : 15kg bag

Test Method : Add 5.0g of activated carbon into 100ml of raw water. Count the cell after 24 hours at 25℃

- Silver activated carbon kills 99.99% of those two germs so it shows a great antibacterial effect.

Caution

– Do not directly let hot water (over 38℃) run through the filter.

* Maximum flow : 0.5Gal/min

* Service life : 1,500G

* Maximum pressure : 125psi

Leave A Comment